Labortechnik

testing equipment

Cell-Instruments

Leak Tester [LT-03]

Micro Leak Tester [MLT-01]

Leak and Seal Strength [LSST-01]

Coefficient of Friction Tester [COF-01]

Gross Leak Tester (Bubble) [GLT-01]

Inclined Coeff. of Friction Tester [COF-03]

Heat Seal Tester [HST-01/02]

Gradient Heat Seal Tester [GHS-01/02]

Hot Tack Tester [HTT-01/02]

Flex Durability Tester [GFT-01/02]

Elmendorf [SLD-01]

Thickness Tester [FFT-01] Peeling Cling Tester [SPC-01] Tensile Tester [TST-01] F e e d b a c k I m p r e s s u m

Elmendorf [SLD-01]

Thickness Tester [FFT-01] Peeling Cling Tester [SPC-01] Tensile Tester [TST-01] F e e d b a c k I m p r e s s u m

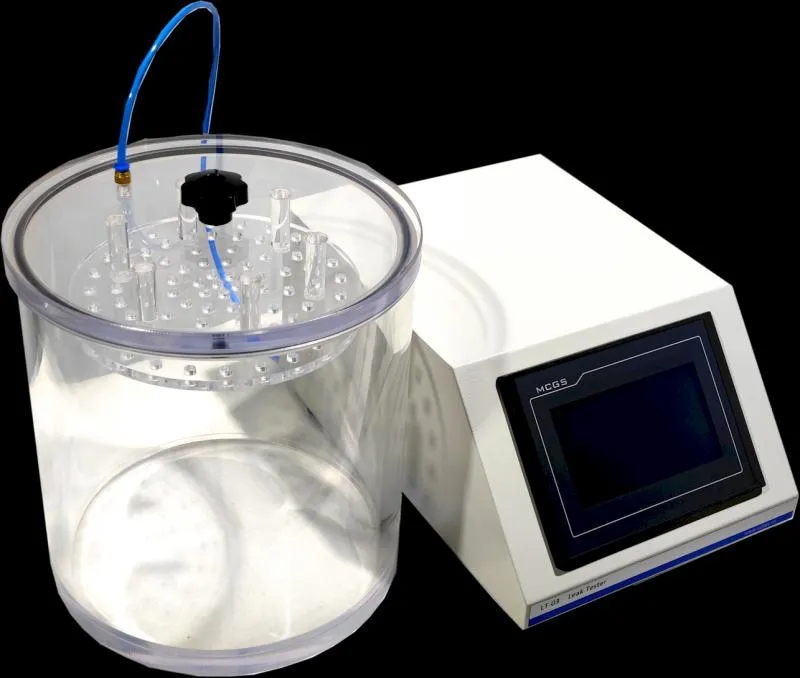

Leak Tester [LT-03]

Leak Tester LT-03: Automatic model, with PLC and HMI touch screen(Vacuum Method)

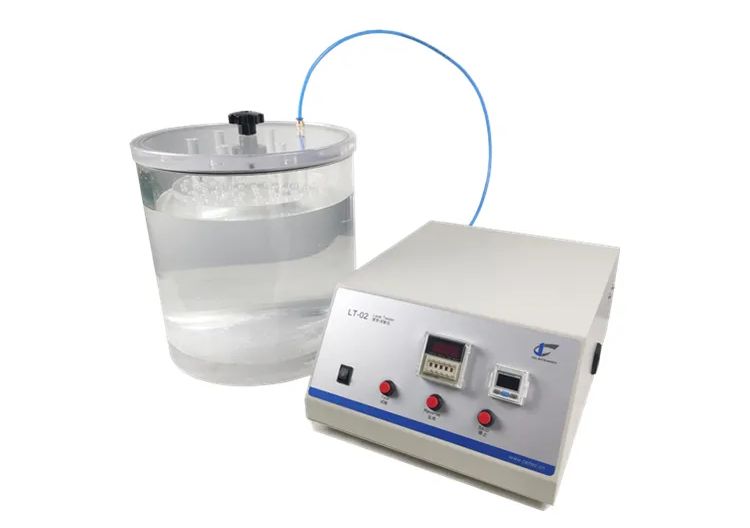

Leak-Tester: LT-02 Automatic model.

Leak-Tester: LT-01 Manual economic model.

Standard: ASTM D3078 “Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission”

Leak Tester is designed for the examination of airproof property of packages, containers, bags, pipes. Leak tester is widely used in food, beverage, pharmaceutical, daily chemical, electrical and electronic industries.

Principle:

A test sample is placed into a vacuum chamber with water and the air above water is evacuated by a venturi tube. A pressure difference is created inside and outside the sample and leakage can be observed and identified when the sample is inflated and a stream of bubbles appeared.

Methylene blue test:

1)The blister is in chamber with solution (Methylene Blue)

2)Vent the chamber and hold the vacuum for a while.

3)Stop the vacuum and hold blister in normal pressure.

The dye enters the blister if there is leak. LT-03 Leak Tester uses vacuum ejector to generate stable vacuum environment. The state-of-the-art human-computer interface and PLC control unit on the leak tester make the parameter setting and test operation direct and easy.Technical data:

Vacuum: 0~-90KPa/0~-13PSI Testing Space: Φ 270mm x 210 mm (H) (Other size available) Gas source: Compressed air Gas Pressure: 0.7MPa/101.5PSI

Technical features:

1. Leak test process all automatic.

2. Touching screen operation.

3. Digital vacuum degree and test time input.

4. Parameters and test data automatic saving.

5. Automatic vacuum maintenance and air reverse.

6. Different chamber sizes available.

7. No vacuum pump required.