Labortechnik

testing equipment

Cell-Instruments

Leak Tester [LT-03]

Micro Leak Tester [MLT-01]

Leak and Seal Strength [LSST-01]

Coefficient of Friction Tester [COF-01]

Gross Leak Tester (Bubble) [GLT-01]

Inclined Coeff. of Friction Tester [COF-03]

Heat Seal Tester [HST-01/02]

Gradient Heat Seal Tester [GHS-01/02]

Hot Tack Tester [HTT-01/02]

Flex Durability Tester [GFT-01/02]

Elmendorf [SLD-01]

Thickness Tester [FFT-01] Peeling Cling Tester [SPC-01] Tensile Tester [TST-01] F e e d b a c k I m p r e s s u m

Elmendorf [SLD-01]

Thickness Tester [FFT-01] Peeling Cling Tester [SPC-01] Tensile Tester [TST-01] F e e d b a c k I m p r e s s u m

Flex Durability Tester [GFT-01/02]

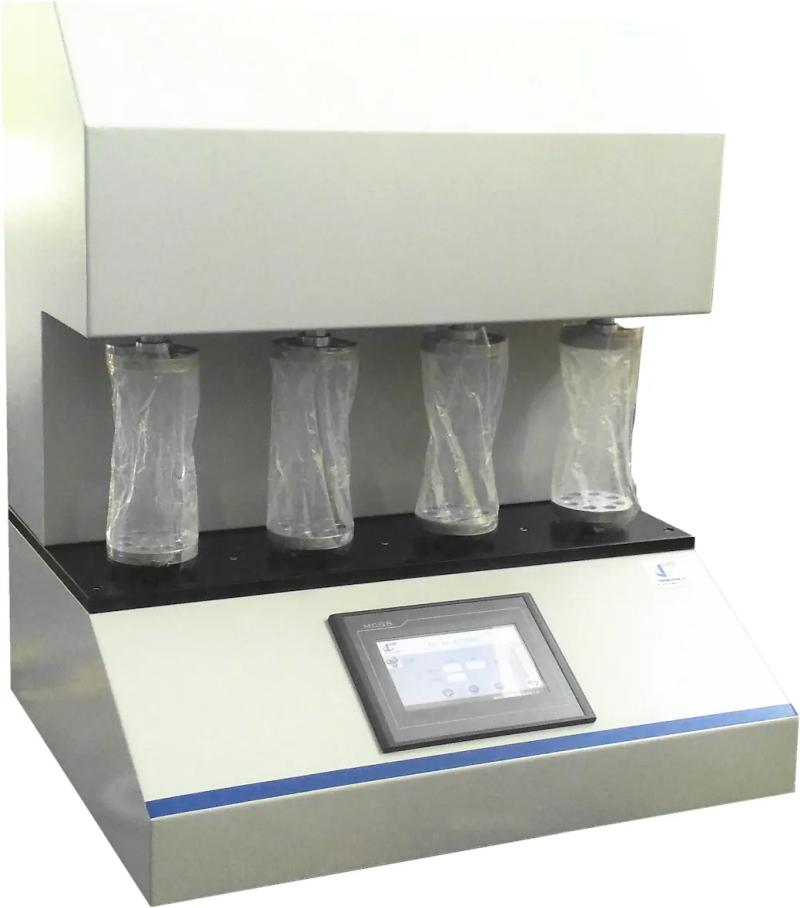

Durability Tester (Gelbo Flex) 4 station

model GFT-01:

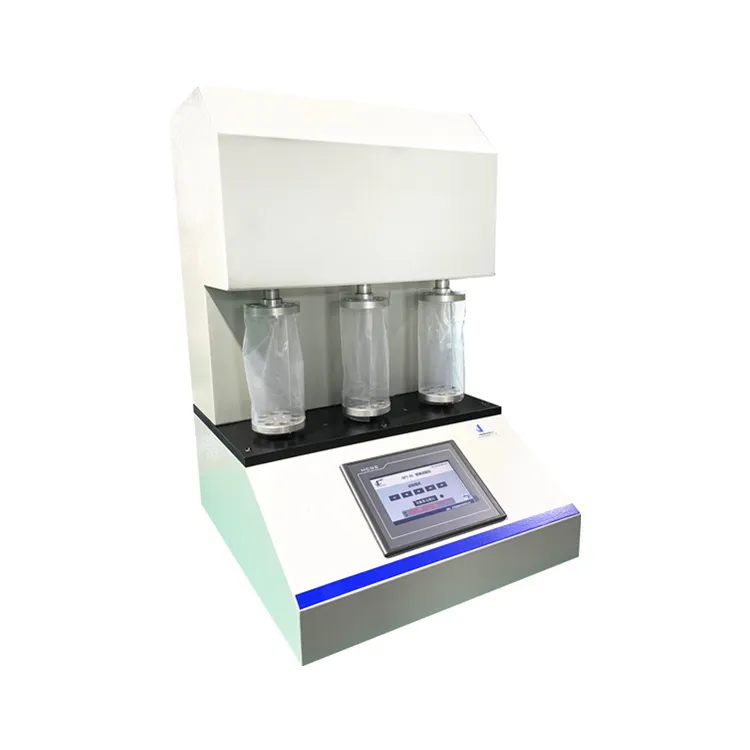

Durability Tester (Gelbo Flex) 3 station

model GFT-02:

Flex Durability Tester (Gelbo Flex)

Standards: ASTM F392, "Flex durability of flexible barrier materials".

The flex durability tester is used to measure the resistance against repetitive strain for films, composites and coating films, etc. Flex failure is determined by measuring the pinholes formed in the sample structure. It is also called Gelboflex.

Principle: The sample size (200 by 280 mm) is attached to the flex tester mandrels. The flexing action consists of a twisting motion combined with a horizontal motion (compression), thus repeatedly twisting and crushing the film. The test set up gives a twisting motion of 440º in the first 90 mm of the stroke and is followed by a straight horizontal motion of 65 mm. The speed is 45 cycles per minute.

Technical Data:

Flex Frequency 45 /minute Flex Angle 440° (90 mm) or 400° (80 mm) Horizontal Stroke 155 mm or 80 mm Stations 4 Sample size 280 mm x 200 mm

Technical features:

1. PLC control and 7 inch touch screen operation.

2. 5 standard test modes and 4 test stations.

3. Long and short stroke fast switching.

4. Protection front cover.

5. Condition A,B,C,D and E can be chosen.

6. Micro printer.

7. Could realize test frequency random settins.